Почему поршневая группа остается сердцем двигателя в 21 веке

Время:2025-11-18 20:01:10

В эпоху стремительного технологического прогресса, когда электромобили и водородные двигатели захватывают заголовки новостей, поршневая группа двигателя внутреннего сгорания (ДВС) продолжает оставаться его незаменимым сердцем. Это не просто метафора, а фундаментальная реальность, укорененная в десятилетиях инженерного совершенства, адаптивности и надежности. Несмотря на вызовы экологии и растущую конкуренцию со стороны альтернативных силовых установок, поршневая группа демонстрирует удивительную устойчивость, эволюционируя и интегрируя инновации, которые делают ее более эффективной, экологичной и жизнеспособной в 21 веке. В этой статье мы глубоко погрузимся в причины этой непреходящей значимости, исследуя исторические корни, современные достижения и будущие перспективы, чтобы понять, почему этот скромный, но критически важный компонент продолжает биться в такт с потребностями человечества.

Исторический контекст: как поршневая группа стала сердцем ДВС

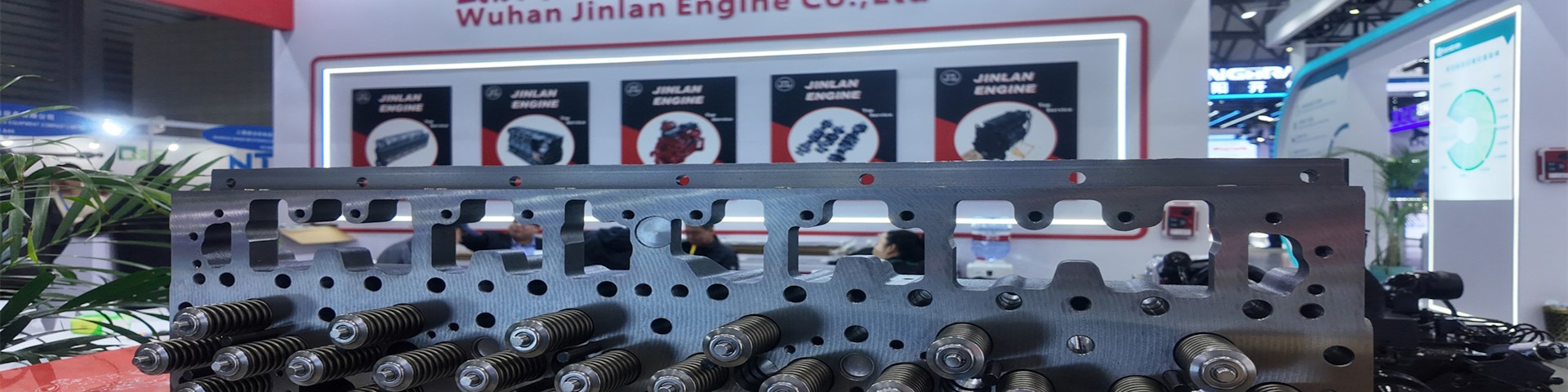

Поршневая группа, состоящая из поршня, поршневых колец, пальца и шатуна, не появилась в одночасье как совершенный механизм. Ее эволюция началась с первых экспериментов 19 века, таких как двигатель Отто 1876 года, который заложил основы четырехтактного цикла. В те времена поршни были простыми, часто изготовленными из чугуна, и служили для преобразования тепловой энергии в механическую движение через возвратно-поступательное действие. Уже тогда инженеры осознали, что именно поршневая группа является центральным элементом, определяющим эффективность и надежность двигателя. Без нее сгорание топлива оставалось бы бесполезным взрывом, а не источником движения.

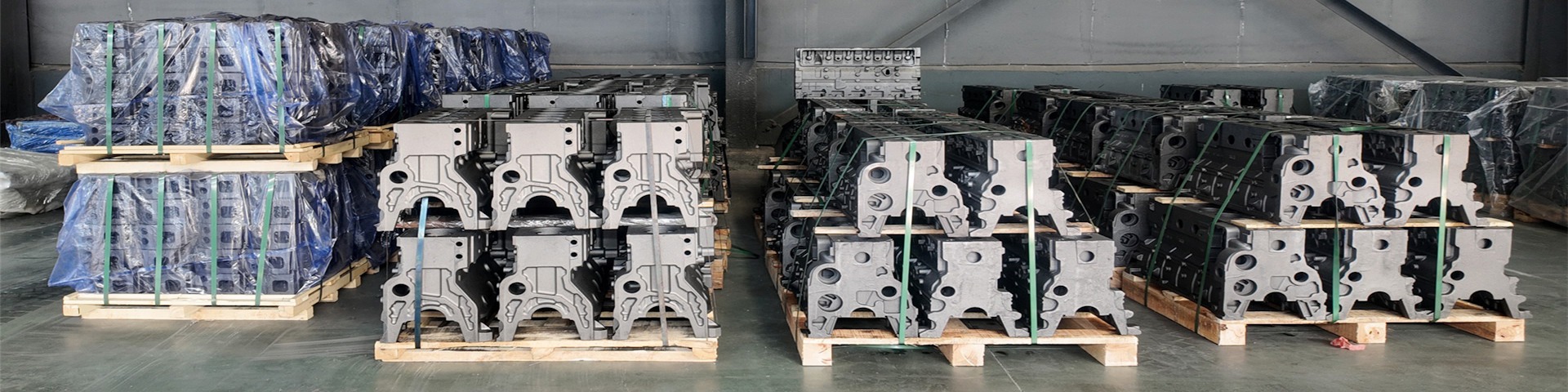

На протяжении 20 века поршневая группа претерпела радикальные изменения, driven by wars, industrialization, and automotive booms. В 1920-х годах внедрение алюминиевых поршней уменьшило вес и улучшило теплоотвод, что повысило общую производительность. К 1950-м годам advancements in metallurgy and machining allowed for tighter tolerances and better sealing through improved piston rings, reducing oil consumption and emissions. Каждая эпоха добавляла слои инноваций: от использования керамических покрытий в 1980-х для снижения трения до компьютерного моделирования в 1990-х, которое оптимизировало форму поршней для максимальной эффективности. Эта историческая траектория показывает, что поршневая группа никогда не была статичной; она всегда адаптировалась, cementing its role as the heart by continuously pumping life into the engine through incremental and revolutionary improvements.

Moreover, the cultural and economic impact of the piston group cannot be overstated. It enabled the mass production of automobiles, fueling global mobility and economic growth. From the Model T to modern supercars, the piston group has been the unsung hero, working silently but indispensably. This historical foundation explains why, even in the 21st century, it remains central—it has proven its worth through over a century of refinement and reliability, making it a trusted component that engineers and consumers alike rely upon.

Фундаментальная роль поршневой группы в работе ДВС

Чтобы понять, почему поршневая группа остается сердцем двигателя, необходимо разобрать ее базовые функции. В самом простом выражении, поршневая группа преобразует энергию сгорания топлива в механическую работу. Это происходит через четыре такта: впуск, сжатие, рабочий ход и выпуск. Поршень, двигаясь в цилиндре, создает давление, которое ignites the fuel-air mixture, and the resulting expansion drives the crankshaft via the connecting rod. Без этой группы, двигатель был бы merely a chamber for explosions, incapable of producing useful motion.

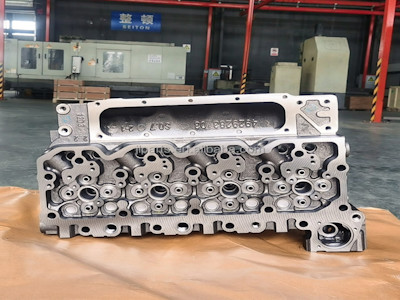

Ключевые аспекты этой роли включают герметизацию, теплообмен и механическую передачу. Поршневые кольца обеспечивают seal between the piston and cylinder wall, preventing leakage of gases and oil, which is crucial for efficiency and emissions control. Одновременно, поршень действует как heat sink, absorbing and dissipating thermal energy to prevent overheating and damage. This dual role of energy conversion and thermal management makes the piston group irreplaceable; alternative designs, such as rotary engines, have struggled to match its balance of simplicity and performance.

In the 21st century, these fundamental roles have only grown in importance. With stricter emissions standards, the sealing function of piston rings has become critical for reducing hydrocarbon emissions. Advances in materials science have led to pistons made from alloys that withstand higher temperatures and pressures, enabling turbocharging and downsizing without sacrificing durability. Thus, the piston group's core functions not only persist but are enhanced, proving that its heart-like role—pumping life and efficiency—is more vital than ever in meeting modern challenges.

Современные инновации и технологические усовершенствования

21 век принес волну инноваций, которые revitalized the piston group rather than rendering it obsolete. One of the most significant advancements is in materials. Modern pistons are often crafted from advanced aluminum-silicon alloys with ceramic or polymer coatings that reduce friction and wear. For example, BMW's use of plasma-sprayed coatings on pistons in their efficient dynamics engines has improved fuel economy by up to 5%. Similarly, piston rings now feature diamond-like carbon (DLC) coatings, which minimize friction and extend lifespan, contributing to lower maintenance costs and better performance.

Computational power has also played a pivotal role. Finite element analysis (FEA) and computational fluid dynamics (CFD) allow engineers to simulate piston behavior under extreme conditions, optimizing shapes for reduced weight and improved strength. This has led to designs like asymmetrical pistons that compensate for thermal expansion, ensuring consistent performance across a wide range of temperatures. Additionally, additive manufacturing (3D printing) is emerging for prototyping and even production of complex piston geometries that were previously impossible, enabling custom solutions for high-performance applications.

Integration with electronic systems is another frontier. Sensors embedded in or near the piston group monitor parameters like temperature, pressure, and knock in real-time, feeding data to engine control units (ECUs) for adaptive tuning. This smart technology allows for dynamic adjustments to ignition timing and fuel injection, maximizing efficiency and minimizing emissions. These innovations demonstrate that the piston group is not a relic but a dynamic component that evolves with technology, solidifying its status as the heart by becoming smarter, lighter, and more efficient.

Экологическая адаптация: ответ на вызовы изменения климата

В ответ на глобальные environmental concerns, поршневая группа has undergone a green transformation. Emissions regulations, such as Euro 6 and EPA standards, have pushed for cleaner combustion, and the piston group is at the forefront of this effort. Improved sealing from advanced piston rings reduces blow-by, which minimizes unburned hydrocarbon emissions. Moreover, designs that promote more complete combustion, such as pistons with optimized bowl shapes, help lower CO2 and NOx outputs. For instance, Mazda's SkyActiv technology uses specially designed pistons to achieve a high compression ratio without knocking, resulting in better fuel efficiency and fewer emissions.

Hybridization and alternative fuels have further integrated the piston group into eco-friendly solutions. In hybrid vehicles, the piston group works in tandem with electric motors, often operating in more efficient ranges thanks to start-stop systems and regenerative braking. This synergy reduces overall fuel consumption. Additionally, adaptations for biofuels, hydrogen, or synthetic fuels show the piston group's versatility; it can handle diverse energy sources with modifications, whereas fully electric systems are limited to electricity. This adaptability makes it a bridge technology in the transition to sustainable mobility, proving that its heart-like role includes pumping not just power but also environmental responsibility.

Looking ahead, research into carbon-neutral engines, such as those running on hydrogen, relies on robust piston groups that can withstand the unique challenges of these fuels. By continuing to innovate, the piston group ensures that internal combustion engines remain a viable part of a diversified energy future, countering the notion that it is outdated in the face of climate change.

Сравнение с альтернативными технологиями: почему поршневая группа сохраняет преимущество

Despite the rise of electric vehicles (EVs) and other alternatives, the piston group maintains distinct advantages that explain its enduring relevance. Cost-effectiveness is a major factor; manufacturing piston groups is well-established and scalable, making internal combustion engines (ICEs) cheaper to produce than EVs, which require expensive batteries and rare materials. This economic efficiency is crucial for mass-market vehicles, especially in developing regions where infrastructure for EVs is lacking.

Performance and reliability are other key areas. ICEs with piston groups offer high power density and quick refueling, advantages for long-distance travel and heavy-duty applications like trucks and machinery. While EVs excel in urban settings, they struggle with range anxiety and charging times. Furthermore, the piston group's proven durability—often lasting hundreds of thousands of kilometers with proper maintenance—contrasts with the shorter lifespan of batteries, which degrade over time. This reliability builds trust among consumers and industries alike.

Technological synergy also plays a role; hybrid systems leverage the best of both worlds, using piston groups for range extension and efficiency. Innovations like variable compression ratio engines, which adjust piston movement dynamically, showcase how the piston group can outperform purely electric solutions in certain scenarios. By comparing these aspects, it becomes clear that the piston group is not being replaced but complemented, retaining its heart-like function due to its unmatched balance of cost, performance, and adaptability.

Будущие перспективы и заключение

Looking to the future, the piston group is poised to remain relevant through continuous innovation. Trends like electrification will likely lead to more integrated systems where piston groups work alongside electric components in series-hybrid or range-extender configurations. Advances in materials, such as graphene composites, could make pistons even lighter and stronger, pushing efficiency boundaries. Additionally, the rise of autonomous vehicles might emphasize reliability over novelty, favoring the tried-and-true nature of piston-based engines.

In conclusion, the piston group's persistence as the heart of the engine in the 21st century is a testament to its foundational importance, adaptability, and ongoing innovation. From its historical roots to modern eco-friendly adaptations, it has proven indispensable. While alternative technologies grow, they often rely on or complement rather than replace this core component. As we navigate the complexities of energy transition, the piston group will continue to pump vitality into mobility, reminding us that sometimes, the heart of a machine is not just a metaphor but a reality built on decades of engineering excellence. Its beat goes on, strong and steady, driving progress forward.