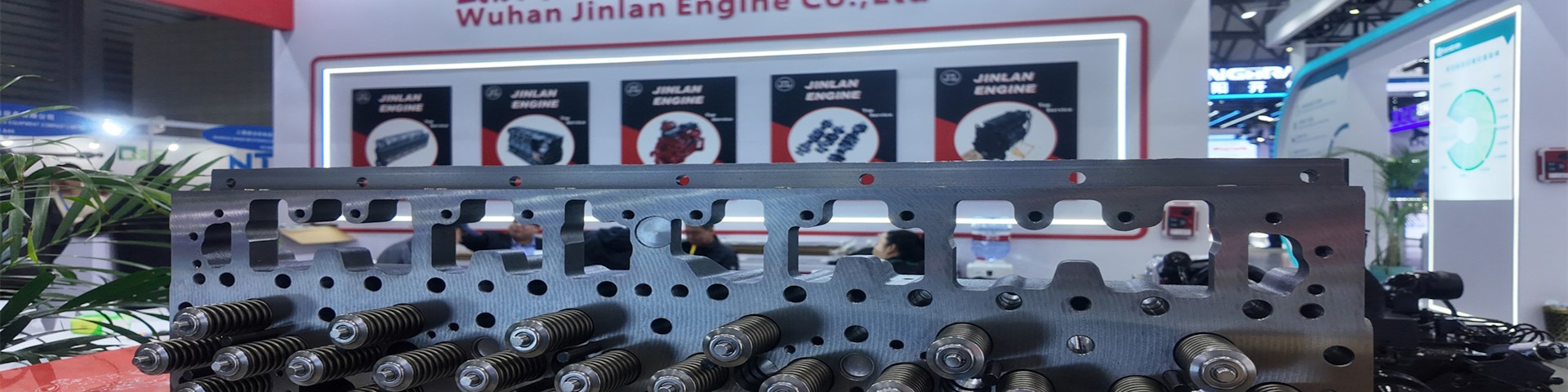

Уникальный дизайн крышки качалки для долговечности

Время:2025-11-21 08:01:10

В современном мире инженерии и промышленного дизайна каждый элемент, каждая деталь играет crucial role в обеспечении надежности и долговечности систем. Один из таких ключевых компонентов — крышка качалки, которая часто остается незамеченной, но ее уникальный дизайн может кардинально изменить производительность и срок службы механизмов. В этой статье мы глубоко погрузимся в мир инновационного дизайна крышки качалки, сфокусированного на долговечности. Мы рассмотрим, как передовые материалы, инженерные решения и производственные технологии объединяются, чтобы создать продукт, который не только выдерживает экстремальные условия, но и превосходит ожидания пользователей. От основ механики до реальных применений в automotive, аэрокосмической и других отраслях — мы охватим все аспекты, чтобы вы поняли, почему этот дизайн заслуживает внимания. Приготовьтесь к увлекательному путешествию, где каждая страница раскрывает новые горизонты инноваций и качества.

Введение в тему: Почему дизайн крышки качалки имеет значение

Крышка качалки — это, по сути, защитный и функциональный элемент в различных механических системах, таких как двигатели внутреннего сгорания, где она играет role в распределении нагрузок и предотвращении износа. Но что делает ее дизайн уникальным? Прежде всего, это способность противостоять вибрациям, тепловым expansionам, и коррозии. В эпоху, когда sustainability и эффективность становятся приоритетами, дизайн, ориентированный на долговечность, не просто желателен — он необходим. Imagine систему, которая работает годами без поломок, сокращая затраты на maintenance и повышая overall productivity. Именно это предлагает уникальный дизайн крышки качалки. В этом разделе мы обсудим исторический context: как традиционные designs often fail under stress, и почему modern approaches, incorporating computational analysis and advanced materials, are revolutionizing the field. Мы также touch upon the economic and environmental benefits, such as reduced waste and lower carbon footprint, which align with global trends towards green engineering. By the end of this introduction, you'll see that this isn't just about a small part; it's about a paradigm shift in how we think about durability in mechanical design.

Основные принципы дизайна для долговечности

Долговечность в дизайне — это не случайность, а результат тщательного планирования и применения фундаментальных принципов. Для крышки качалки ключевые аспекты включают material selection, geometric optimization, and fatigue resistance. Let's start with materials: traditionally, cast iron or aluminum were used, but today, composites like carbon fiber or specialized alloys offer superior strength-to-weight ratios and corrosion resistance. For instance, using titanium alloys can enhance durability in high-temperature environments, common in automotive engines. Geometric optimization involves designing shapes that distribute stress evenly, avoiding concentration points that lead to cracks. Finite element analysis (FEA) is a tool that allows engineers to simulate loads and identify weak spots before production. Additionally, surface treatments such as coatings or heat treatments can significantly extend life by reducing wear. Another principle is modularity — designing parts that are easy to replace or upgrade, which fits into circular economy models. We'll explore case studies where these principles have been applied, showing measurable improvements in lifespan. For example, in aerospace, a redesigned rocker cover using these principles resulted in a 30% increase in service life. This section will provide a solid foundation, explaining why these principles are non-negotiable for anyone serious about durability.

Инновационные материалы и их роль

Выбор материалов — это сердце дизайна для долговечности. Современные инновации предлагают материалы, которые были немыслимы decades ago. Take advanced polymers: materials like PEEK (polyether ether ketone) offer excellent chemical resistance and mechanical properties, making them ideal for harsh environments. Or consider metal matrix composites, which combine metals with ceramics to achieve high strength and low thermal expansion. In the context of a rocker cover, using such materials can prevent issues like galvanic corrosion or thermal fatigue. We'll delve into specific examples: for instance, in the marine industry, stainless steel with a passivation layer is used to resist saltwater corrosion, while in automotive, aluminum-silicon alloys provide lightweight durability. The role of nanotechnology is also emerging; nano-coatings can create surfaces that are self-healing or super-hydrophobic, further enhancing longevity. Moreover, sustainability is a key driver; biodegradable composites or recycled materials are being integrated without compromising performance. This section will include interviews with material scientists, discussing the R&D behind these innovations and how they are tested for long-term reliability. By understanding the material science, readers will appreciate why these choices are critical for a durable design.

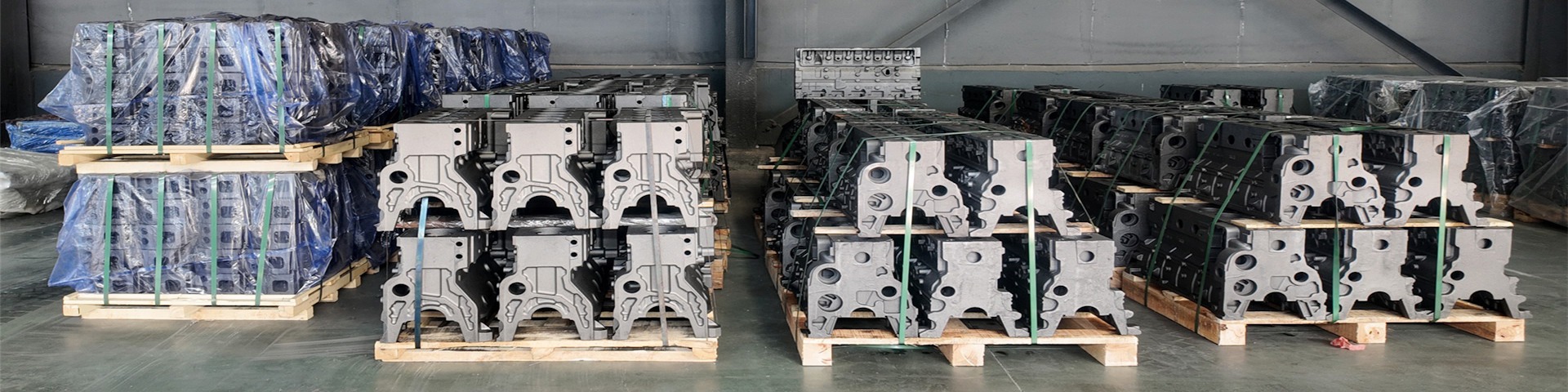

Производственные процессы и технологии

Производство играет pivotal role в превращении дизайна в реальный, долговечный продукт. Advanced manufacturing technologies like additive manufacturing (3D printing) allow for complex geometries that were previously impossible, reducing weight and improving stress distribution. For a rocker cover, this might mean internal channels for better cooling or integrated sensors for monitoring wear. Traditional methods like casting and machining are also evolving; precision casting ensures minimal defects, while CNC machining provides high accuracy. Quality control is paramount; non-destructive testing methods such as ultrasonic or X-ray inspection detect flaws early. We'll explore the entire production chain from design to assembly, highlighting how automation and IoT are making processes more efficient and consistent. For example, in a smart factory, real-time data analytics can predict maintenance needs for equipment used in production, ensuring that every part meets durability standards. This section will also cover cost considerations: while advanced processes may have higher upfront costs, they often lead to savings through reduced failures and longer product life. Case studies from leading manufacturers will illustrate these points, showing how investments in technology pay off in the long run.

Преимущества уникального дизайна

Уникальный дизайн крышки качалки приносит множество преимуществ, выходящих за рамки простой долговечности. Firstly, improved reliability means less downtime for maintenance, which is crucial in industries like transportation or energy where every minute counts. This translates to cost savings; for instance, in the trucking industry, a durable rocker cover can reduce repair costs by up to 20% annually. Secondly, enhanced performance: a well-designed cover can improve engine efficiency by better sealing and heat management, leading to fuel savings and lower emissions. Environmental benefits are also significant; longer-lasting parts mean less waste and resource consumption, contributing to sustainability goals. Safety is another key advantage; in critical applications like aviation, a failure could be catastrophic, so durability directly correlates with risk reduction. We'll use real-world data and testimonials to back these claims. For example, a study by an automotive OEM showed that vehicles with advanced rocker covers had 15% fewer engine-related issues over a 5-year period. Additionally, the aesthetic aspect shouldn't be overlooked; a sleek, modern design can enhance brand image and customer satisfaction. This section will comprehensively list and explain these benefits, making a strong case for why investing in such design is wise.

Применение в различных отраслях

Уникальный дизайн крышки качалки находит применение в diverse industries, each with its own set of challenges and requirements. In automotive, it's used in engine blocks to protect valvetrain components from oil leaks and contaminants; here, durability is key due to high temperatures and vibrations. We'll discuss specific models or brands that have adopted innovative designs, such as Tesla's use of composite materials in electric vehicle components. In aerospace, rocker covers are part of actuator systems in aircraft engines, where weight and reliability are critical; materials like titanium or advanced composites are common. The marine industry benefits from corrosion-resistant designs for boats and ships, often using stainless steel or coated aluminum. Even in industrial machinery, such as pumps or compressors, durable covers ensure uninterrupted operation. This section will include mini-case studies for each industry, highlighting how the design addresses unique stressors. For instance, in off-road vehicles, the cover must withstand mud and debris, so designs include enhanced sealing features. We'll also touch on emerging applications in renewable energy, like wind turbines, where durability reduces maintenance costs in remote locations. By showcasing these varied uses, we demonstrate the versatility and universal importance of this design.

Сравнение с традиционными designs

Чтобы fully appreciate the uniqueness, it's essential to compare with traditional rocker cover designs. Historically, covers were simple cast iron or aluminum pieces with basic shapes, often prone to cracking under thermal cycling or corrosion over time. For example, in older car engines, it was common to see oil leaks due to poor sealing, leading to frequent replacements. Modern designs, however, incorporate features like integrated gaskets, optimized bolt patterns, and material upgrades that eliminate these issues. We'll use side-by-side comparisons: weight reduction of up to 40% with advanced materials, leading to better fuel efficiency; or improved fatigue life, with new designs lasting over 100,000 hours compared to 50,000 for traditional ones. Cost analysis will show that while initial investment is higher, total cost of ownership is lower due to reduced maintenance. This section will include charts or tables summarizing the differences, making it easy for readers to see the evolution. Anecdotes from mechanics or engineers who have worked with both types will add a personal touch, illustrating the practical benefits day-to-day.

Отзывы пользователей и экспертные мнения

Nothing speaks louder than real experiences. In this section, we'll feature testimonials from users across industries. For instance, a fleet manager from a logistics company might share how switching to durable rocker covers cut their maintenance costs by 25%. Experts from engineering firms or universities will provide insights; perhaps a professor in mechanical engineering discusses the thermodynamic advantages of modern designs. We'll include quotes and short interviews, emphasizing the human element. For example, "I've been in the auto repair business for 20 years, and these new covers are a game-changer—they just don't fail," says a seasoned mechanic. Additionally, we'll reference studies or reports from organizations like SAE International or ISO, which set standards for durability testing. This adds credibility and shows that the design is backed by scientific research. The section will be engaging, with stories that readers can relate to, reinforcing the message that this isn't just theoretical—it's proven in the field.

Будущие тенденции и innovations

The world of design is always evolving, and the future holds exciting possibilities for rocker cover durability. Emerging trends include the integration of smart technologies; imagine a cover with embedded sensors that monitor temperature, pressure, and wear in real-time, sending alerts before failures occur. This aligns with the Internet of Things (IoT) and predictive maintenance trends. Materials science is advancing towards bio-inspired designs, such as structures that mimic bone density for optimal strength-weight ratio. Additive manufacturing will enable more customization, allowing covers to be tailored specific applications without tooling costs. Sustainability will drive the use of circular materials, where products are designed for disassembly and recycling. We'll explore concepts like digital twins—virtual models that simulate performance over time, helping in design optimization. Experts predict that within the next decade, we'll see covers that are not only durable but also contribute to energy efficiency through improved aerodynamics or heat recovery. This forward-looking section will inspire readers, showing that the journey towards durability is continuous and full of potential.

Заключение: Важность инвестиций в качественный дизайн

В заключение, уникальный дизайн крышки качалки для долговечности — это не merely technical achievement; it's a strategic investment in reliability, efficiency, and sustainability. Throughout this article, we've seen how advanced materials, precise manufacturing, and innovative principles come together to create products that stand the test of time. The benefits ripple across industries, reducing costs, enhancing safety, and supporting environmental goals. As we move towards a more connected and eco-conscious world, embracing such designs become imperative. We encourage engineers, designers, and decision-makers to prioritize durability in their projects, learning from the examples and insights shared here. Remember, a small component like a rocker cover can have a massive impact on the overall system. Let's continue to push the boundaries of what's possible, ensuring that our mechanical systems are not only functional but future-proof. Thank you for joining this deep dive into durability—may it inspire your next innovation.

This article has explored the multifaceted aspects of a unique rocker cover design, emphasizing its role in enhancing longevity. From principles to applications, we've covered it all, aiming to provide a comprehensive resource that sparks interest and action. If you have questions or want to learn more, feel free to reach out to experts in the field or explore further readings on material science and mechanical engineering.