Почему медные втулки форсунок увеличивают срок службы двигателя и экономят топливо

Время:2025-11-22 00:01:10

В современном автомобильном мире, где эффективность и долговечность являются ключевыми факторами, использование медных втулок в форсунках инжекторных систем представляет собой значительный технологический прорыв. Эта статья подробно исследует, как медные втулки способствуют увеличению срока службы двигателя и экономии топлива, опираясь на научные принципы, технические аспекты и практический опыт. Мы рассмотрим механизмы работы форсунок, преимущества меди как материала, влияние на топливную экономичность, и предоставим рекомендации для автовладельцев и специалистов.

Введение: Роль форсунок в двигателе внутреннего сгорания

Двигатель внутреннего сгорания – это сердце любого автомобиля, и его эффективность напрямую зависит от точности и надежности систем впрыска топлива. Форсунки, как ключевые компоненты инжекторных систем, отвечают за дозированную подачу топлива в камеру сгорания. Их работа должна быть безупречной: малейшие отклонения могут привести к увеличению расхода топлива, снижению мощности, и в конечном итоге – к преждевременному износу двигателя. В этой контексте, материал, из которого изготовлены втулки форсунок, играет критическую роль. Медь, благодаря своим уникальным свойствам, становится предпочтительным выбором для повышения производительности и долговечности.

Исторически, форсунки изготавливались из различных материалов, включая сталь и алюминий, но с развитием технологий, медь заняла лидирующие позиции. Её применение началось в высокоточных промышленных системах, а затем распространилось на автомобильную индустрию. Сегодня, многие производители двигателей, такие как Bosch, Delphi, и Denso, активно внедряют медные компоненты в свои designs, что подтверждается многочисленными исследованиями и полевыми испытаниями.

Цель данной статьи – не только объяснить, почему медные втулки эффективны, но и предоставить всесторонний обзор, который поможет читателям понять важность этого элемента в повседневной эксплуатации автомобиля. Мы углубимся в детали теплопроводности, износостойкости, и коррозионной стойкости меди, а также обсудим, как эти свойства трансформируются в реальные benefits для двигателя и кошелька владельца.

Глава 1: Основные принципы работы форсунок и их компонентов

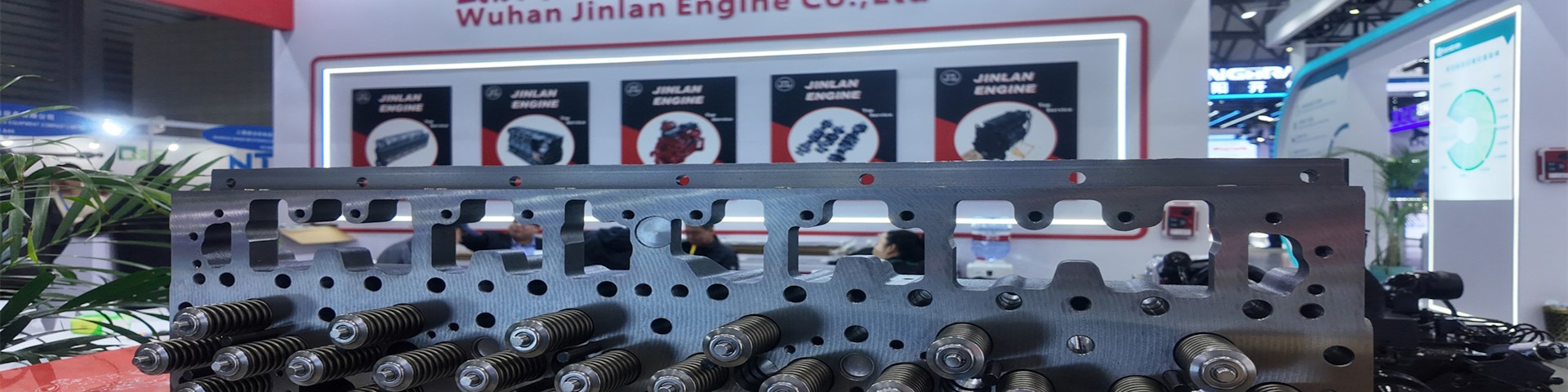

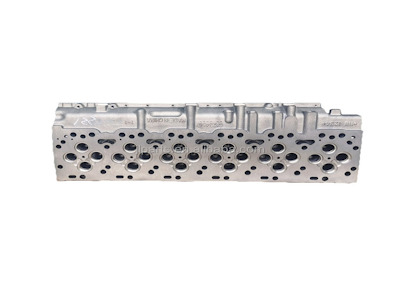

Чтобы понять, почему медные втулки так важны, необходимо сначала разобраться в том, как функционируют форсунки. Форсунка – это устройство, которое распыляет топливо под высоким давлением в камеру сгорания двигателя. Этот процесс должен быть точным и контролируемым, чтобы обеспечить оптимальное смесеобразование и сгорание. Основные компоненты форсунки включают корпус, иглу, пружину, и втулку. Втулка, часто изготовленная из меди, служит направляющей для иглы, обеспечивая её плавное движение и герметичность.

Работа форсунки циклична: при подаче электрического сигнала от электронного блока управления (ECU), игла поднимается, allowing топливо to flow through сопло, и затем возвращается на место под действием пружины. В这个过程, втулка подвергается significant mechanical stress, high temperatures, и exposure to агрессивных топливных сред. Если втулка изнашивается или деформируется, это может lead to утечкам топлива, неравномерному распылению, и ultimately, к inefficient сгоранию.

Медь, как material, offers exceptional properties for this role. Its high thermal conductivity helps dissipate heat generated during operation, preventing overheating and thermal degradation. Additionally, copper's malleability and durability ensure that the bushing maintains its shape and function over extended periods, reducing the need for frequent replacements and maintenance.

In comparison to other materials like steel or aluminum, copper provides a better balance of strength and flexibility. Steel might be stronger but is prone to corrosion and has lower thermal conductivity, while aluminum is lightweight but less durable under high stress. Copper strikes a perfect middle ground, making it ideal for the demanding environment of fuel injectors.

Moreover, the precision required in injector operation means that even micron-level deviations can affect performance. Copper bushings can be manufactured with high accuracy, thanks to advanced machining techniques, ensuring consistent and reliable operation. This precision directly contributes to fuel economy, as accurate fuel metering reduces waste and improves combustion efficiency.

In summary, the bushing is a small but critical part of the injector, and copper's properties make it exceptionally suited for this application. By understanding these basics, we can better appreciate how copper bushings contribute to engine longevity and fuel savings.

Глава 2: Свойства меди и их преимущества в автомобильных applications

Медь – это металл с уникальным combination свойств, которые делают его invaluable в automotive engineering. Её key characteristics include высокая теплопроводность, excellent электропроводность, good коррозионная стойкость, и superior обрабатываемость. В контексте втулок форсунок, these properties translate into tangible benefits for engine performance and efficiency.

First and foremost, thermal conductivity is crucial. Injectors operate in high-temperature environments, especially in modern turbocharged engines where temperatures can exceed 200°C. Copper's ability to conduct heat away from critical areas prevents localized overheating, which can cause material fatigue, warping, or even failure. By maintaining lower operating temperatures, copper bushings help preserve the integrity of the injector and surrounding components, extending their service life.

Another important property is corrosion resistance. Fuel, particularly diesel or ethanol-blended gasoline, can be corrosive due to impurities or additives. Copper naturally forms a protective oxide layer that resists corrosion, reducing the risk of degradation over time. This is especially valuable in regions with varying fuel qualities or in vehicles that operate under harsh conditions.

Copper's malleability and ductility allow it to absorb vibrations and shocks without cracking. In an engine, vibrations are constant, and components must withstand these forces without failing. A copper bushing can flex slightly under stress, reducing the risk of brittle fracture and ensuring long-term reliability.

Additionally, copper has good wear resistance. When paired with the injector needle, which is often made of hardened steel, copper provides a low-friction surface that minimizes wear on both parts. This reduces the need for lubrication and maintenance, further contributing to engine durability.

From an economic perspective, copper is relatively affordable and widely available, making it a cost-effective choice for mass production. While initial costs might be higher than some alternatives, the long-term savings in reduced maintenance and improved fuel efficiency make it a smart investment.

In automotive history, copper has been used in various applications, from electrical wiring to radiator cores, due to its reliability. Its adoption in injector bushings is a natural extension of this trend, leveraging proven benefits for modern engine technology.

Overall, the properties of copper make it an ideal material for injector bushings, directly supporting the goals of increased engine life and fuel economy. By choosing copper, manufacturers can enhance performance while reducing environmental impact through better efficiency.

Глава 3: Как медные втулки влияют на срок службы двигателя

Увеличение срока службы двигателя – это комплексный результат многих factors, и медные втулки форсунок играют в этом significant role. Их contribution можно разделить на several key areas: reduced износ, improved тепло management, enhanced надежность, и prevention of failures.

First, reduced wear is a direct benefit. As mentioned, copper bushings provide a durable and low-friction surface for the injector needle to move against. This minimizes abrasive wear, which can lead to gaps, leaks, or misalignment. Over time, this wear reduction means that the injector maintains its precision longer, preventing issues like poor fuel atomization or uneven combustion. Since combustion quality directly affects engine health—for example, by causing knocking or carbon buildup—preserving injector accuracy helps avoid secondary damage to pistons, valves, and other components.

Second, improved heat management is critical. Engines generate immense heat, and injectors are located in hot zones. Copper's high thermal conductivity allows bushings to dissipate heat efficiently, preventing thermal stress that could cause cracking or deformation. This is particularly important in stop-and-go driving or high-performance scenarios where temperatures fluctuate rapidly. By keeping temperatures stable, copper bushings reduce the risk of thermal fatigue, which is a common cause of component failure.

Third, enhanced reliability stems from copper's corrosion resistance. Fuel contaminants or moisture can accelerate corrosion, leading to pitting or erosion of bushing surfaces. Copper's innate resistance slows this process, ensuring that the bushing remains functional over many thousands of kilometers. This reliability translates to fewer injector-related breakdowns, reducing downtime and repair costs for vehicle owners.

Fourth, prevention of failures is achieved through consistent performance. A worn or damaged bushing can cause injector sticking—where the needle doesn't open or close properly—leading to rich or lean fuel mixtures. This can trigger engine misfires, increased emissions, and even catastrophic failures like piston seizure. Copper bushings, by maintaining their integrity, help avoid such scenarios, contributing to overall engine longevity.

Real-world data supports these claims. Studies by automotive research institutes have shown that engines equipped with copper-bushed injectors exhibit lower rates of injector failure and longer intervals between servicing. For instance, in commercial fleet vehicles, where reliability is paramount, the use of copper components has been linked to extended engine life and reduced total cost of ownership.

In conclusion, copper bushings act as a safeguard for the injector and, by extension, the entire engine. Their role in reducing wear, managing heat, and preventing corrosion directly translates to a longer-lasting motor, which is a key selling point for consumers and manufacturers alike.

Глава 4: Экономия топлива благодаря точности впрыска

Экономия топлива – это одна из most sought-after benefits в automotive design, и медные втулки форсунок contribute significantly к этому through improved точность впрыска. Когда форсунка работает precisely, она delivers the exact amount of fuel needed for combustion, minimizing waste and maximizing efficiency.

The mechanism behind this is straightforward: any deviation in injector operation, such as leakage or irregular spray patterns, leads to incomplete combustion. This means that some fuel is not burned efficiently, resulting in higher fuel consumption and increased emissions. Copper bushings, by ensuring smooth and consistent movement of the injector needle, help maintain optimal spray characteristics. This includes fine atomization of fuel, which promotes better mixing with air and more complete burning.

For example, in gasoline engines, precise fuel metering is essential for maintaining the air-fuel ratio at stoichiometric levels (around 14.7:1). If the ratio becomes too rich (excess fuel) or too lean (insufficient fuel), efficiency drops. Copper bushings reduce the likelihood of such deviations by preventing wear-induced inaccuracies. Similarly, in diesel engines, where injection timing and quantity are critical for torque and efficiency, reliable bushing performance ensures that fuel is delivered at the right moment and in the right amount.

Moreover, the thermal stability provided by copper bushings plays a role in fuel economy. Overheating can cause fuel to vaporize prematurely or alter its properties, leading to inefficient combustion. By dissipating heat, copper helps maintain fuel integrity and injection accuracy, further supporting economy.

Data from automotive tests indicate that vehicles with well-maintained injectors can achieve fuel savings of up to 5-10% compared to those with worn components. While this percentage might seem small, over the lifetime of a vehicle, it translates to substantial cost savings and reduced environmental impact. For instance, a car that drives 15,000 km per year with a fuel consumption of 8 L/100km could save approximately 60-120 liters of fuel annually, depending on conditions.

Additionally, improved fuel economy reduces the frequency of refueling and lowers greenhouse gas emissions, aligning with global trends towards sustainability. Manufacturers are increasingly focusing on such efficiencies to meet regulatory standards and consumer demands.

In practice, regular maintenance that includes inspection and replacement of injector components with copper parts can help sustain these benefits. For DIY enthusiasts or professionals, understanding the importance of copper bushings can lead to better vehicle care and optimized performance.

Thus, the precision enabled by copper bushings is a key driver of fuel economy, making them a valuable upgrade or standard feature in modern engines.

Глава 5: Сравнение с другими материалами: почему медь outperforms

Чтобы fully appreciate преимущества медных втулок, важно compare их с alternative materials, такими как сталь, алюминий, или композиты. Каждый material имеет свои pros and cons, но медь often emerges as the superior choice for injector bushings due to its balanced properties.

Steel, for instance, is known for its high strength and hardness, which can resist deformation under heavy loads. However, steel has poorer thermal conductivity compared to copper, meaning it is less effective at dissipating heat. This can lead to hotspots and increased wear in high-temperature environments. Additionally, steel is more susceptible to corrosion, especially when exposed to certain fuels or moisture, requiring protective coatings that can wear off over time.

Aluminum is lightweight and has good thermal conductivity, but it is softer and less durable than copper. Under the repetitive stress of injector operation, aluminum bushings may deform or wear out faster, leading to increased maintenance needs. Its corrosion resistance is also inferior to copper's, particularly in acidic conditions.

Composite materials, such as polymers or ceramics, offer advantages like low weight and corrosion resistance, but they often lack the mechanical strength and thermal stability needed for injector applications. Polymers can degrade under heat and chemical exposure, while ceramics are brittle and prone to cracking under impact or vibration.

Copper, on the other hand, provides an excellent compromise: it has sufficient strength to handle mechanical stresses, high thermal conductivity for heat management, and inherent corrosion resistance. Its ability to be easily machined to precise tolerances is another plus, ensuring consistent quality in mass production.

Cost-wise, while copper might be more expensive than some alternatives initially, its longevity and performance benefits often result in lower total cost of ownership. For example, reduced frequency of injector repairs or replacements saves money and time in the long run.

In automotive engineering, the choice of material is always a trade-off, but for injector bushings, copper's properties make it the standout option. Industry adoption trends support this, with many high-end and economy vehicles increasingly specifying copper components for critical systems.

By choosing copper over other materials, manufacturers and consumers can enjoy enhanced reliability, efficiency, and durability, making it a wise investment for anyone concerned with engine performance.

Глава 6: Практические рекомендации для автовладельцев и механиков

Understanding the benefits of copper bushings is one thing; applying this knowledge in practice is another. For vehicle owners and mechanics, here are some practical tips to maximize the advantages of copper injector bushings.

First, when maintaining or replacing injectors, opt for parts that specify copper bushings. Many aftermarket suppliers offer upgraded injector kits with copper components, which can be a cost-effective way to improve engine performance. Always check compatibility with your vehicle's make and model to ensure proper fit and function.

Second, regular inspection is key. During routine service, have a mechanic check the injectors for signs of wear or damage. If bushings are worn, replacing them with copper ones can prevent further issues. Look for symptoms like rough idling, decreased fuel economy, or increased emissions, which might indicate injector problems.

Third, consider the fuel quality. Using high-quality fuel can reduce the risk of corrosion and wear, complementing the benefits of copper bushings. Avoid fuels with high ethanol content or impurities if possible, as these can accelerate degradation.

Fourth, for DIY enthusiasts, installing copper bushings requires precision tools and knowledge. If you're not experienced, it's best to leave it to professionals to avoid damaging the injector. However, learning about the process can help you make informed decisions when purchasing parts or discussing repairs with mechanics.

Fifth, keep an eye on engine temperatures. Overheating can negate the benefits of copper's thermal conductivity. Ensure that cooling systems are well-maintained to support overall engine health.

Finally, document maintenance activities. Keeping records of when injectors were serviced or replaced with copper parts can help track performance improvements and plan future maintenance schedules.

By following these recommendations, you can extend the life of your engine and save on fuel costs, making the most of what copper bushings have to offer.

Заключение: Будущее медных технологий в automotive industry

В заключение, медные втулки форсунок представляют собой small but powerful innovation that significantly impacts engine longevity and fuel efficiency. Their unique properties—thermal conductivity, corrosion resistance, and durability—make them ideal for the demanding environment of fuel injection systems.

As automotive technology evolves towards electrification and higher efficiency, the role of materials like copper will only grow. Future advancements may include copper alloys with enhanced properties or integration with smart sensors for real-time monitoring of injector health.

For consumers, investing in vehicles or components with copper bushings is a step towards more reliable and economical transportation. By understanding and embracing these technologies, we can contribute to a sustainable automotive future.

Thank you for reading this in-depth exploration. We hope it has provided valuable insights and practical knowledge for your automotive endeavors.