Главный подшипник болт прочность и надежность

Время:2025-12-10 16:01:10

В современном машиностроении и инженерной практике прочность и надежность компонентов, таких как главный подшипник и болты, играют критически важную роль. Эти элементы являются основой многих механических систем, от автомобилей и промышленного оборудования до аэрокосмической техники. Недостаточная прочность или ненадежность может привести к катастрофическим отказам, дорогостоящему простою и даже угрозе безопасности. Поэтому глубокое понимание факторов, влияющих на прочность и надежность, а также внедрение передовых методов проектирования, материалов и обслуживания, является неотъемлемой частью инженерного подхода. В этой статье мы подробно рассмотрим, как обеспечить оптимальную производительность главного подшипника и болтов через призму прочности и надежности, опираясь на научные принципы и практический опыт.

1. Введение в тему прочности и надежности

Прочность и надежность – это два взаимосвязанных понятия в инженерии, которые определяют способность компонента выдерживать нагрузки без разрушения и функционировать без сбоев в течение заданного времени. Для главного подшипника, который часто является опорным элементом в вращающихся механизмах, и болтов, используемых для крепления, эти характеристики становятся особенно важными. Прочность относится к максимальной нагрузке, которую материал или компонент может выдержать перед failure, в то время как надежность охватывает вероятность безотказной работы в различных условиях. В контексте машиностроения, высокие стандарты прочности и надежности требуют тщательного выбора материалов, точного проектирования, rigorous testing, и регулярного обслуживания. Эта статья aims to provide a comprehensive overview, covering theoretical foundations, practical applications, and future trends, to help engineers and professionals enhance the durability and safety of their systems.

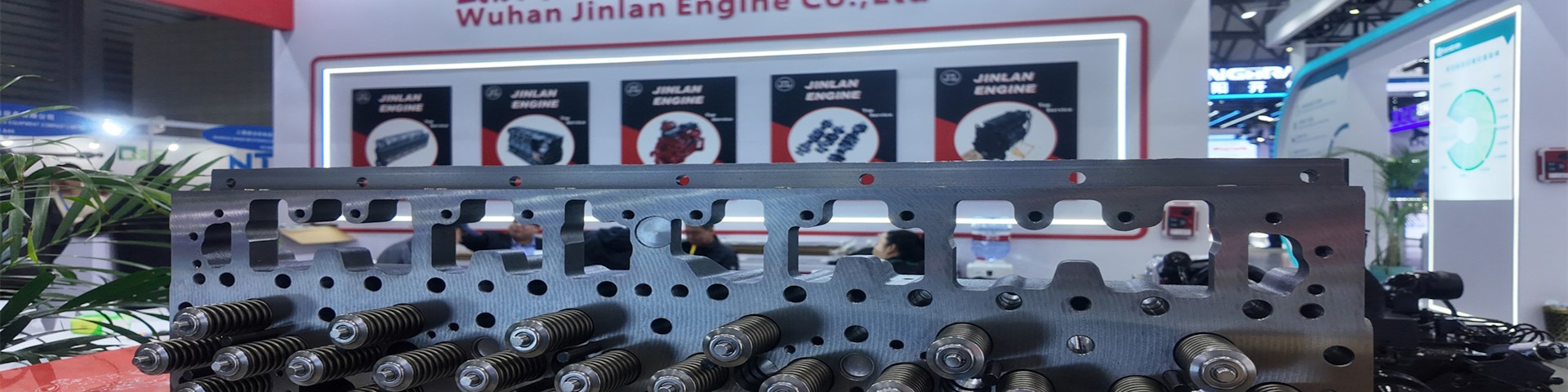

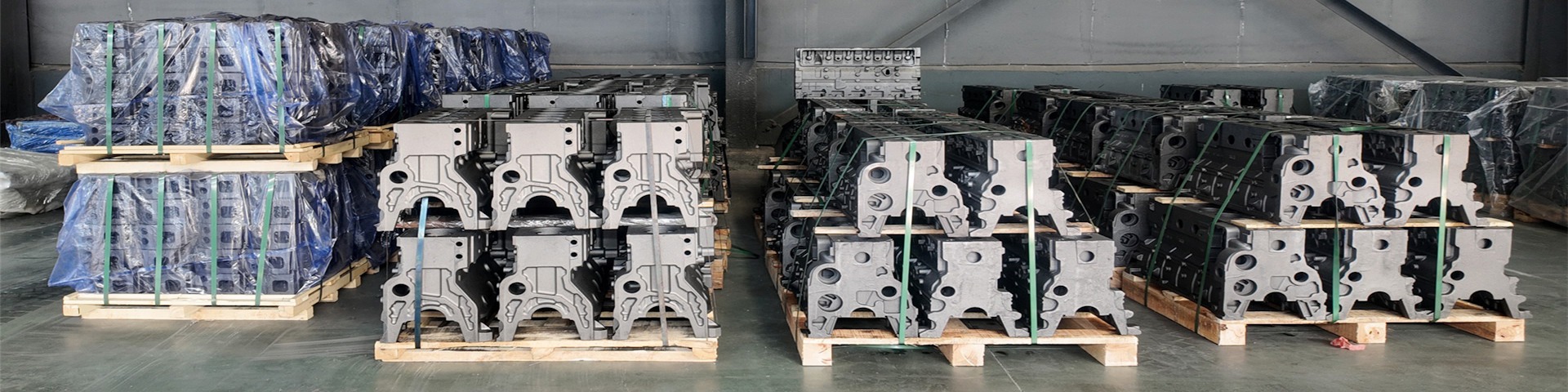

2. Основные понятия: что такое главный подшипник и болт?

Главный подшипник – это тип подшипника, typically used in applications where high radial or axial loads are present, such as in engines, turbines, or heavy machinery. It supports the main shaft or rotor, allowing smooth rotation while minimizing friction and wear. Bolts, on the other hand, are threaded fasteners used to join components together, applying clamping force to prevent loosening under vibration or load. The interaction between bolts and bearings is crucial; for example, bolts secure bearing housings or mounts, and their failure can directly impact bearing performance. Understanding the basic mechanics – such as load distribution, stress concentrations, and fatigue – is essential for designing reliable systems. Materials commonly used include steel alloys for bolts and various grades of steel or ceramics for bearings, each with specific properties tailored to different environments.

3. Факторы, влияющие на прочность

Прочность компонентов зависит от множества факторов, включая material properties, geometric design, manufacturing processes, and operational conditions. For bolts, tensile strength, yield strength, and hardness are key metrics, influenced by alloy composition and heat treatment. For bearings, factors like hardness, toughness, and resistance to wear and corrosion determine their load-carrying capacity. Geometric aspects, such as thread design in bolts or raceway curvature in bearings, affect stress distribution and potential failure points. Manufacturing defects, like inclusions or surface imperfections, can significantly reduce strength. Additionally, environmental factors such as temperature, humidity, and exposure to chemicals can degrade materials over time. By analyzing these factors through finite element analysis (FEA) and experimental testing, engineers can optimize designs to maximize strength and prevent premature failures.

4. Методы обеспечения надежности

Надежность достигается через proactive measures such as robust design, quality control, predictive maintenance, and redundancy. In design, using safety factors and fatigue analysis helps account for uncertainties and cyclic loads. For bolts, proper torque application and use of locknuts or adhesives can prevent loosening. For bearings, lubrication and alignment are critical to reduce wear and extend life. Quality control during manufacturing, including non-destructive testing like ultrasonic or magnetic particle inspection, ensures components meet specifications. Predictive maintenance, using vibration analysis or thermography, allows early detection of issues before they lead to failure. Implementing redundancy, such as multiple bolts or backup bearings, can enhance system reliability in critical applications. These methods, combined with regular training and adherence to standards, form a holistic approach to reliability engineering.

5. Материалы и их выбор для повышения прочности

Выбор материалов является фундаментальным для обеспечения прочности. Для болтов常用 high-strength steel alloys like ASTM A574 or corrosion-resistant alloys such as stainless steel for harsh environments. Bearings often use chrome steel, ceramic hybrids, or polymers depending on load and speed requirements. Advanced materials like titanium or composites offer high strength-to-weight ratios but may come with higher costs. Material selection should consider mechanical properties (e.g., hardness, toughness), environmental resistance (e.g., to heat or chemicals), and compatibility with other components. Heat treatment processes, such as quenching and tempering, can enhance strength by altering microstructure. Additionally, surface treatments like plating or coating (e.g., zinc or DLC) improve corrosion resistance and reduce friction. Collaborating with material scientists and using databases like MatWeb can aid in selecting the optimal material for specific applications, balancing performance, cost, and availability.

6. Проектирование и инженерные расчеты

Проектирование компонентов involves detailed engineering calculations to ensure they can withstand expected loads. For bolts, calculations include determining preload, stress area, and factors of safety based on standards like VDI 2230. For bearings, life calculations using the L10 life formula (based on load and speed) help estimate durability. Finite element analysis (FEA) is a powerful tool for simulating stress分布 and identifying weak points. CAD software allows for precise modeling and iteration. Considerations such as bolt spacing, bearing clearance, and thermal expansion must be integrated into the design. Dynamic analysis for vibrational loads and fatigue analysis for cyclic stresses are also crucial. Engineers should follow industry standards (e.g., ISO or DIN) and use software like ANSYS or SolidWorks for accurate predictions. Iterative testing and prototyping validate designs before full-scale production, reducing the risk of failure in real-world applications.

7. Тестирование и контроль качества

Тестирование является vital для verification прочности и надежности. Destructive tests, such as tensile testing for bolts or fatigue testing for bearings, provide data on ultimate strength and endurance limits. Non-destructive tests (NDT), including ultrasonic, radiographic, or magnetic particle inspection, detect internal flaws without damaging components. Quality control during manufacturing involves dimensional checks, hardness testing, and surface finish analysis. For bolts, torque-tension testing ensures proper clamping force. For bearings, running tests under load simulate operational conditions. Statistical process control (SPC) monitors production consistency. Accreditation to standards like ISO 9001 ensures a systematic approach to quality. Field testing in real environments provides additional validation. Documentation and traceability, through lot tracking and certification, help maintain quality over time. Regular audits and continuous improvement processes, such as Six Sigma, further enhance reliability by reducing variability and defects.

8. Обслуживание и продление срока службы

Правильное обслуживание significantly extends the life of components. For bolts,定期 inspection for loosening, corrosion, or wear is essential; re-torquing may be necessary after initial settlement. Use of thread lockers or prevailing torque nuts can maintain clamp load. For bearings, lubrication is critical – choosing the right lubricant type (grease or oil) and schedule based on operating conditions reduces friction and prevents seizure. Monitoring for unusual noises, vibrations, or temperature rises can indicate problems. Alignment checks ensure that shafts and bearings are properly positioned to avoid excessive loads. Predictive maintenance technologies, such as vibration analysis or oil analysis, detect early signs of failure. Training personnel on proper handling and installation techniques prevents damage during maintenance. Replacement schedules based on usage hours or condition monitoring help avoid unexpected failures. Implementing a computerized maintenance management system (CMMS) can streamline these processes and improve overall reliability.

9. Примеры из практики и case studies

Real-world examples illustrate the importance of прочности и надежности. In the automotive industry, failures of crankshaft bearings due to inadequate lubrication have led to engine seizures; cases show that using high-quality oils and regular changes can prevent this. In aerospace, bolt failures in aircraft structures have caused accidents; investigations often reveal issues with material fatigue or improper torque, leading to enhanced standards and testing. Industrial machinery, such as wind turbines, relies on robust bearing and bolt systems; a case study might detail how predictive maintenance reduced downtime by 20%. Another example could be in construction equipment, where corrosion-resistant bolts extended service life in harsh environments. These case studies highlight best practices and lessons learned, emphasizing the value of integrated design, quality control, and proactive maintenance. They also demonstrate economic impacts, such as cost savings from reduced repairs and increased productivity.

10. Будущие тенденции и инновации

Будущее прочности и надежности lies in innovation and technology. Advancements in materials science, such as nanomaterials or smart materials with self-healing properties, could revolutionize component durability. Additive manufacturing (3D printing) allows for complex geometries and customized designs that optimize strength and weight. IoT and sensors enable real-time monitoring of bolts and bearings, providing data for predictive maintenance and reducing unplanned downtime. Artificial intelligence and machine learning can analyze large datasets to predict failures and optimize maintenance schedules. Sustainability trends drive the development of recyclable materials and energy-efficient designs. In robotics and automation, reliability is paramount, leading to new standards and testing methods. Collaboration across industries fosters knowledge sharing and accelerated innovation. As global challenges like climate change and resource scarcity emerge, engineers must focus on creating more resilient and efficient systems, ensuring that прочность и надежность remain at the forefront of engineering excellence.

11. Заключение

В заключение, прочность и надежность главного подшипника и болтов являются cornerstone инженерной практики,直接影响 безопасность, эффективность и стоимость владения механических систем. Через comprehensive approach, включая тщательный выбор материалов, точное проектирование, rigorous testing, и proactive обслуживание, можно достичь высоких уровней производительности. Будущие инновации promise even greater advancements, but the fundamental principles remain unchanged: understand the loads, respect the materials, and maintain vigilance. By prioritizing these aspects, инженеры и professionals can ensure that their systems operate reliably for years to come, contributing to overall industrial progress and safety.

Эта статья предоставила обзор ключевых аспектов, и мы надеемся, что она послужит valuable resource для тех, кто стремится улучшить прочность и надежность в своих проектах. Для дальнейшего изучения, обратитесь к стандартам ISO, технической литературе, и консультациям с экспертами в области.