Что такое турбонагнетатель и как он работает в автомобиле

Время:2025-12-14 16:01:10

В современном автомобильном мире турбонагнетатель стал неотъемлемой частью многих двигателей, предлагая уникальное сочетание мощности, эффективности и экологичности. Но что же такое турбонагнетатель, и как он работает? В этой статье мы подробно разберем принципы его функционирования, преимущества, недостатки и практические аспекты использования в автомобилях. Эта тема особенно актуальна в эпоху, когда производители стремятся снизить выбросы и повысить производительность двигателей без существенного увеличения их размера.

1. Введение в турбонагнетатели

Турбонагнетатель, или просто турбина, — это устройство, которое использует энергию выхлопных газов для увеличения количества воздуха, поступающего в двигатель. Это позволяет двигателю сжигать больше топлива и, следовательно, производить больше мощности. Идея турбонагнетателя не нова: первые патенты на подобные устройства появились еще в начале XX века, но широкое распространение они получили только во второй половине века, особенно в спортивных и коммерческих автомобилях.

Основная цель турбонагнетателя — повысить эффективность двигателя. Без турбины двигатель relies solely on natural aspiration, which limits the amount of air it can intake. With a turbocharger, the engine can achieve higher compression ratios and better performance from a smaller displacement, making it ideal for modern engines that need to meet strict emission standards while delivering power.

2. Принцип работы турбонагнетателя

Турбонагнетатель состоит из двух основных компонентов: турбины и компрессора, соединенных общим валом. Турбина приводится в действие выхлопными газами, которые выходят из двигателя. Эти газы обладают высокой температурой и pressure, и当他们 проходят через турбину, они вращают ее колесо. Это вращение передается через вал на компрессор, который, в свою очередь, сжимает воздух и нагнетает его во впускной коллектор двигателя.

Процесс начинается, когда двигатель работает: выхлопные газы направляются в корпус турбины, где они расширяются и вращают турбинное колесо. Скорость вращения может достигать десятков тысяч оборотов в минуту. Компрессор, находящийся на другом конце вала, засасывает воздух из атмосферы, сжимает его и подает под pressure в двигатель. Это увеличение давления воздуха позволяет впрыснуть больше топлива, что приводит к более мощному взрыву в цилиндрах и, следовательно, к увеличению мощности.

Ключевым аспектом работы является использование энергии, которая otherwise would be wasted. В традиционных двигателях выхлопные газы просто выбрасываются в атмосферу, но турбонагнетатель harnesses this energy to improve efficiency. This not only boosts power but also can improve fuel economy under certain conditions, as the engine can achieve the same power output with less fuel compared to a naturally aspirated engine of larger size.

3. Компоненты турбонагнетателя

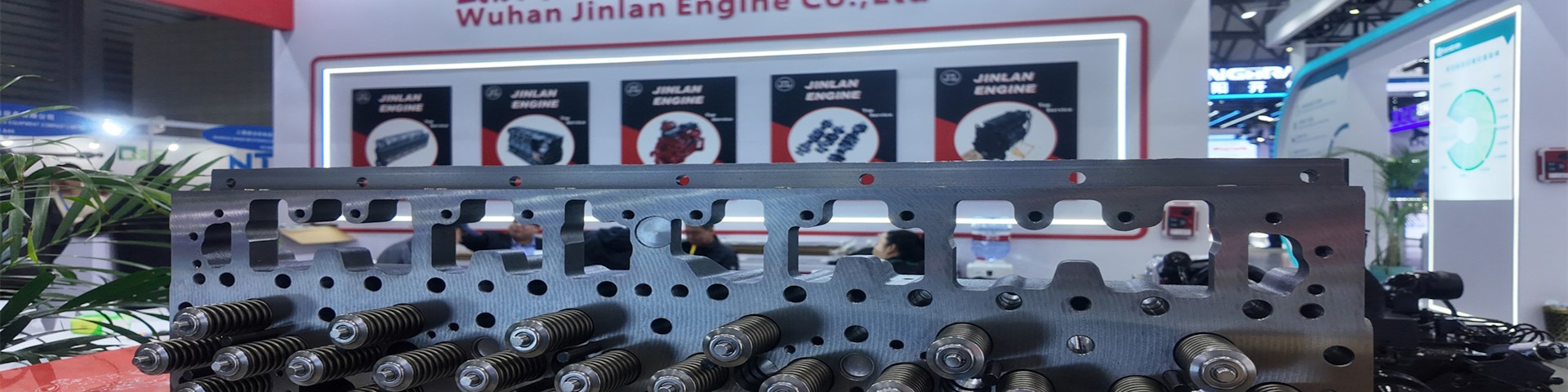

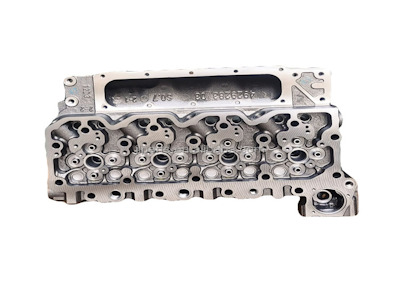

Турбонагнетатель — это сложное устройство, состоящее из нескольких critical parts. Основные компоненты включают:

- Турбинное колесо: Расположено в выхлопной части, оно вращается под действием выхлопных газов. Изготовлено из жаропрочных материалов, таких как инконель или керамика, чтобы withstand high temperatures.

- Компрессорное колесо: Находится во впускной части, оно сжимает воздух и направляет его в двигатель. Обычно made from aluminum or titanium for lightweight and durability.

- Вал: Соединяет турбинное и компрессорное колеса, передавая rotation. Он must be precisely balanced to avoid vibrations and ensure smooth operation at high speeds.

- Корпус: Housing that contains the wheels and directs the flow of gases and air. Often made from cast iron or aluminum, with heat-resistant coatings.

- Подшипники: Support the shaft and allow it to rotate freely. Modern turbochargers use ball bearings or journal bearings, which are lubricated by engine oil to reduce friction and wear.

- Интеркулер:虽然不是 часть самого турбонагнетателя, но часто используется в conjunction with it. Интеркулер охлаждает сжатый воздух before it enters the engine, increasing its density and improving combustion efficiency.

Каждый из этих компонентов играет vital role in the overall performance. For example, the materials used must handle extreme conditions: temperatures can exceed 1000°C in the turbine section, while the compressor side deals with high pressures and speeds. Advances in materials science have led to more reliable and efficient turbochargers over the years.

4. Преимущества использования турбонагнетателя

Турбонагнетатели offer numerous benefits that make them popular in automotive applications. One of the primary advantages is increased power output. By forcing more air into the engine, a turbocharger can significantly boost horsepower and torque without increasing engine size. This is particularly useful for small-displacement engines, allowing them to compete with larger naturally aspirated engines in terms of performance.

Another key benefit is improved fuel efficiency. Because the engine can produce more power from a given amount of fuel, it can operate more efficiently under load. This is known as downsizing: manufacturers use smaller engines with turbochargers to achieve the same performance as larger engines, but with better fuel economy and lower emissions. For instance, a 1.5-liter turbocharged engine might deliver power equivalent to a 2.0-liter naturally aspirated engine, while consuming less fuel.

Turbochargers also contribute to reduced emissions. By enabling more complete combustion, they help lower levels of harmful pollutants like carbon monoxide and hydrocarbons. Additionally, the use of turbo technology allows engines to meet stringent emission standards, such as Euro 6 or EPA regulations, without sacrificing performance.

From a driver's perspective, turbocharged engines provide better responsiveness and acceleration. Modern turbochargers are designed to minimize turbo lag—the delay between pressing the accelerator and feeling the boost. With technologies like variable geometry turbos or twin-scroll designs, lag is reduced, making driving more enjoyable and dynamic.

5. Недостатки и challenges

Despite their advantages, turbochargers come with some drawbacks. One of the most commonly cited issues is turbo lag. This is the time it takes for the turbo to spool up and provide boost, especially at low engine speeds. While advancements have mitigated this, it can still be noticeable in some applications, affecting driving feel.

Another challenge is heat management. Turbochargers generate immense heat, which can lead to problems like heat soak, where components overheat and performance degrades. This requires additional cooling systems, such as oil coolers or intercoolers, adding complexity and cost to the vehicle.

Reliability can also be a concern. Turbochargers operate under extreme conditions, leading to wear and tear on components like bearings and seals. If not properly maintained, they can fail, resulting in expensive repairs. Regular maintenance, including oil changes and inspections, is crucial to ensure longevity.

Cost is another factor. Turbocharged engines are generally more expensive to produce and purchase than naturally aspirated ones. However, the long-term benefits in fuel savings and performance often offset this initial cost for many consumers.

Lastly, turbochargers can increase engine complexity, making repairs and diagnostics more challenging for mechanics. This necessitates specialized knowledge and tools, which might not be readily available in all repair shops.

6. Типы турбонагнетателей

There are several types of turbochargers designed for different applications. The most common include:

- Однотурбинные системы: Use a single turbocharger, suitable for most passenger cars. They are cost-effective and provide a good balance of performance and efficiency.

- Твин-турбо системы: Employ two turbochargers, which can be arranged in parallel or sequence. Parallel setups use two turbos of the same size to reduce lag, while sequential systems use a small turbo for low RPM and a larger one for high RPM, optimizing performance across the rev range.

- Турбонагнетатели с изменяемой геометрией (VGT): Feature adjustable vanes that optimize gas flow at different speeds, reducing lag and improving efficiency. Commonly used in diesel engines.

- Электрические турбонагнетатели: A recent innovation that uses an electric motor to spool up the turbo instantly, eliminating lag. These are becoming more popular in hybrid and high-performance vehicles.

Each type has its own advantages. For example, VGT turbos are excellent for providing consistent boost, while electric turbos offer immediate response but at a higher cost. The choice depends on the vehicle's intended use, such as economy, sport, or commercial applications.

7. Применение в автомобилях

Turbochargers are used in a wide range of vehicles, from economy cars to luxury sedans and trucks. In passenger cars, they help achieve a blend of performance and fuel efficiency. For instance, many compact cars now feature turbocharged engines that deliver spirited acceleration without guzzling fuel.

In the sports car segment, turbochargers are almost ubiquitous. Brands like Porsche, Audi, and BMW use them to extract maximum power from their engines, often in combination with other technologies like direct injection. This allows for smaller, lighter engines that still produce exhilarating performance.

Commercial vehicles, such as trucks and buses, benefit from turbochargers by improving torque at low RPMs, which is essential for hauling heavy loads. Diesel engines, in particular, rely heavily on turbocharging to meet power and emission standards.

Even in the emerging electric vehicle market, turbo-like technologies are being explored. For example, some EVs use electric compressors to enhance performance, though this is different from traditional turbocharging.

The adoption of turbochargers is also driven by regulatory pressures. As governments worldwide impose stricter emission norms, manufacturers turn to turbocharging as a way to downsize engines and reduce CO2 output without compromising on driveability.

8. Обслуживание и уход

Proper maintenance is key to ensuring the longevity and performance of a turbocharger. Here are some essential tips:

- Регулярная замена масла: Use high-quality oil and change it at recommended intervals. Turbochargers rely on engine oil for lubrication, and dirty oil can cause damage.

- Прогрев и остывание: Allow the engine to warm up before driving hard, and let it idle for a minute after high-speed driving to cool down the turbo. This prevents oil coking and extends turbo life.

- Проверка утечек: Inspect for leaks in the intake and exhaust systems, as leaks can reduce efficiency and cause damage.

- Использование качественного топлива: Poor fuel can lead to carbon buildup, affecting turbo performance.

- Профессиональный осмотр: Have a mechanic check the turbo during routine services to catch issues early.

Neglecting maintenance can lead to common problems like turbo failure, which often manifests as loss of power, excessive smoke from the exhaust, or unusual noises. Addressing these signs promptly can prevent costly repairs.

9. Будущее турбонагнетателей

The future of turbocharging looks promising, with ongoing innovations aimed at improving efficiency and reducing environmental impact. One trend is the integration of turbochargers with hybrid systems. For example, electric辅助 turbos can provide instant boost, complementing the internal combustion engine and enhancing overall performance.

Advances in materials, such as the use of ceramics and composites, are making turbos more durable and efficient. These materials can withstand higher temperatures and reduce weight, contributing to better vehicle dynamics.

Another area of development is smart turbocharging, where electronic controls optimize turbo performance based on driving conditions. This can further reduce lag and improve fuel economy.

As the automotive industry shifts towards electrification, turbochargers may evolve or be replaced by other technologies, but for the foreseeable future, they remain a crucial tool for balancing power, efficiency, and emissions in internal combustion engines.

10. Заключение

Турбонагнетатель — это ingenious device that has revolutionized automotive engineering. By harnessing waste energy from exhaust gases, it enhances engine performance, improves fuel economy, and helps reduce emissions. While there are challenges like turbo lag and maintenance requirements, the benefits far outweigh the drawbacks for most applications.

As technology advances, we can expect even more efficient and reliable turbochargers, ensuring their place in the future of transportation. Whether you're a car enthusiast or a everyday driver, understanding how a turbocharger works can help you appreciate the engineering marvel under your hood and make informed decisions about vehicle maintenance and purchases.

In summary, the turbocharger is a key enabler of modern automotive progress, blending power with sustainability in a way that few other technologies can match.